Search

There is a strong shift toward automation

Sharwan Agnihotri, Head - Mining & Export Business, HD Hyundai Construction Equipment (India), speaks on the role of the Hi-Track digital solution, and how it enhanced the management and monitoring of mining excavators.

Safety is an integral part of our product design

Narasimha Jayakumar, CEO, Greaves Retail

Eicher Trucks and Buses Launches Eicher Pro X Range at Bharat Mobility

Co-developed with leading logistics service providers.

We provide comprehensive lifecycle support for mining excavators

Sharwan Agnihotri, Head – Mining and Export Business, HD Hyundai Construction Equipment (India), speaks on the company’s approach to providing lifecycle support for mining excavators, including refurbishment options and Extended LifeSeries machines.

Grading the Future

As the demand for advanced road networks and improved connectivity continues to surge, the clamor for motor graders in the construction industry is reaching unprecedented heights.

Poised for growth

As coal mining activity escalates, the need for tipper trucks will rise.

Mandatory AC cabins for truck drivers by 2025!

Starting in 2025, all truck cabins will be required to have air conditioning, offering much-needed comfort to drivers who endure sweaty conditions during their 11-12 hour shifts.

Fuelling the future

Backhoe loader manufacturers are developing hybrid or fully electric backhoe loaders, which significantly reduce or eliminate fuel consumption and emissions.

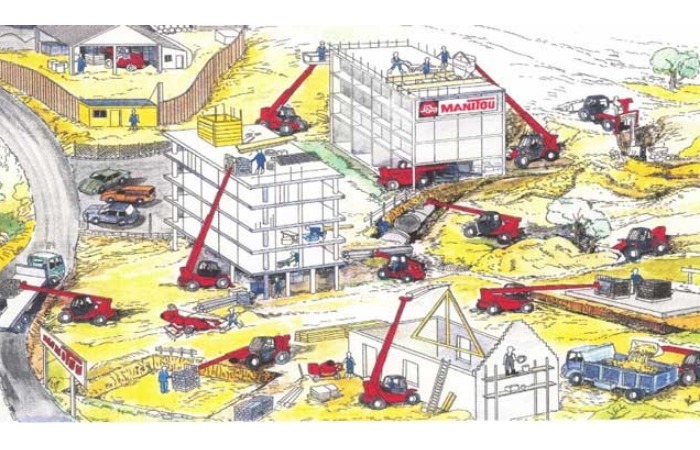

The Versatile Workhorse

Telehandlers can perform a wide range of tasks in various industries.

Technology drives John Deere’s 25-year success in India

Over its 25 years, John Deere has shown significant commitment to investment in manufacturing and product development in India

Up-grading roads!

The road construction industry in India is undergoing a paradigm shift. Robust demand, higher investment and significant policy support in the road construction industry are driving the demand for motor graders in India.

Road construction drives demand for motor graders

Surat Mehta, Head of SDLG Business in India

Poised to higher grow

The demand for telehandlers has been increasing steadily, especially from the infrastructure construction and mining segments over the coming years.

Demand for reliable material handling products is fast growing

Deepak Shetty of JCB India speaks on the market for telehandlers in India

JCB’s zero Tailswing 50Z-1 compact excavator

JCB has expanded its range of compact excavators with the zero tail-swing 50Z-1, boosting dig depth to 12 feet 7 inches and dump height to 14 feet over its predecessor, the 48Z.

Upgrading Technology

Commonly used to construct and maintain gravel and dirt roads, motor graders have also prepared building foundations and drainage ditches, making them popular with government agencies and contractors.

Technological upgrades are perennial part of CE industry: Sandeep Mathur of CASE

Sandeep Mathur, Brand Leader, CASE India, speaks on the current scenario of motor graders in India, and the upcoming digital technologies in motor graders.

New Liebherr excavators for Félix Giorgetti Sàrl

Félix Giorgetti Sàrl family business has purchased two new crawler excavators from Liebherr.

Fuel cost savings at cement plant

Fuel cost savings at cement plant Volvo's EC950EL heavyweight excavator consistently delivers fuel-cost savings and performance gains for the local cement producer at their limestone quarry in Andhra Pradesh.

"Motor grader market in India is growing at 40 per cent"

Roads sector remains the biggest growth driver of motor graders in India. VG Sakthikumar, Managing Director, Schwing Stetter Sales and Services, elaborates more on the market and technology trends in motor graders.

Building homes with ease

Elevo Group South Africa, a leading Portuguese group in all engineering and construction sectors on a large and small scale, selected Carmix machines based on their reliability, efficiency and ease of use for an important project lasting approximately two years: the construction of 500 houses in Massingir, a small village in Mozambique, near the Kruger natural park.

Revival on Cards?

India is witnessing an improved growth trend in coal mining, as Coal India Ltd (CIL) is aiming an output of one billion tonne by 2020. CIL has earmarked a capital investment of Rs 57,000 crore, as part of the road map for one billion tonne target, with a planned capex of Rs 8,500 crore in 2017-18.

Essential for Road Building

Commitment towards infrastructural development and faster implementation of road projects to desired specifications are driving the growth of the motor grader market in India.

Leadership Through Innovation

Volvo Trucks entered the Indian commercial vehicle (CV) industry 17 years ago with a clear goal, to drive the change. The company focused on the mining transportation segment in India and realised that our brand promise was more relevant than ever before.

Wheel loaders - Optimising Productivity

Cycle time is a critical success factor in all bulk handling applications. Ramifications of high cycle time even extend to bulk handlers securing business. Wheel loaders are extensively used bulk handling tools wherein high productivity is of essence.

ElectroMech Cranes to Support BMM Ispat

BMM Group has placed order for 13 cranes with ElectroMech for its ongoing steel plant expansion project. BMM Ispat is a Rs 2,000-crore company, part of the renowned BMM Group. The plant at Danapur, Hospet, Karnataka

Operator Cabin Design

Advandes designs and builds state-of-the-art cabins for the material handling and equipment industry adhering to safety standards at affordable costs. Advandes Design engineering services based in Pune is offering services in new product development.

Powered for the long haul

Commercial vehicle OEMs - domestic and global - have pumped in investments, augmented capacities, launched global platform strategies, enhanced touch points, and stressed on soft solutions to suit the demands of emerging markets.

We are going to add a few new products soon.

We have a turnover of about Rs 350 crore, out of which 10 per cent is from the equipment sector, says Nishant Jairath, Director Marketing, Metalman Auto. Excerpts of the interview.Could you elaborate on Metalman Auto?s product range?Metalman Auto manufactures various types of sheet metal and tubular fabricated assemblies with surface treatments. Our product range comprises cabins for construction equipment, loader arms and tower assembly. We supply our products to various original equipmen

Scooptram ST18

Atlas Copco is launching a new, 18-tonne capacity underground loader for large operations including development work as well as production mining. Scooptram ST18, the new loader, is expected to be the most productive LHD on the market.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com